-

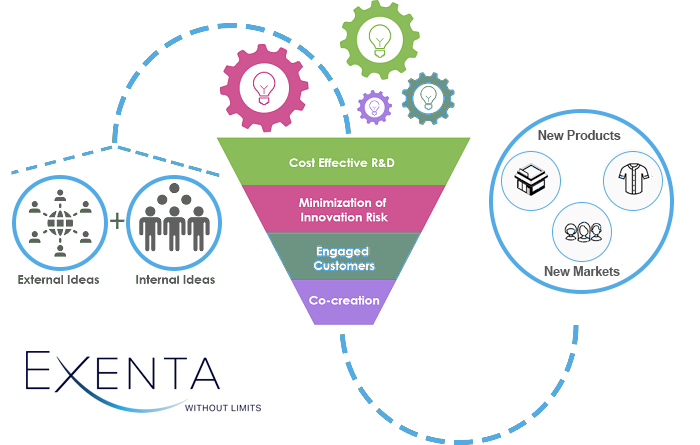

Exenta Revolutionizes Innovation Lifecycle Management

-

Level Up Your Business with Innovation Lifecycle Management

-

Remote Collaboration and the Power of Cloud-Based PLM

-

How to Take Your Brand Direct-to-Consumer (DTC)

-

Exenta ERP Solution Improves Efficiency and Accuracy

-

Carhartt Becomes Trusted PPE Manufacturer

-

COVID-19 Resources for Fashion and Sewn Goods

-

Covercraft Shifts to Making PPE for Healthcare Professionals

-

How to Empower Visually Impaired Workers on the Shop Floor

-

Healing Hands Donates PPE to Healthcare Workers