-

How to Optimize Profits Through Returns Management

-

Exenta Has Joined Aptean, Inc.

-

Four Biggest Problems Facing Fashion Manufacturers

-

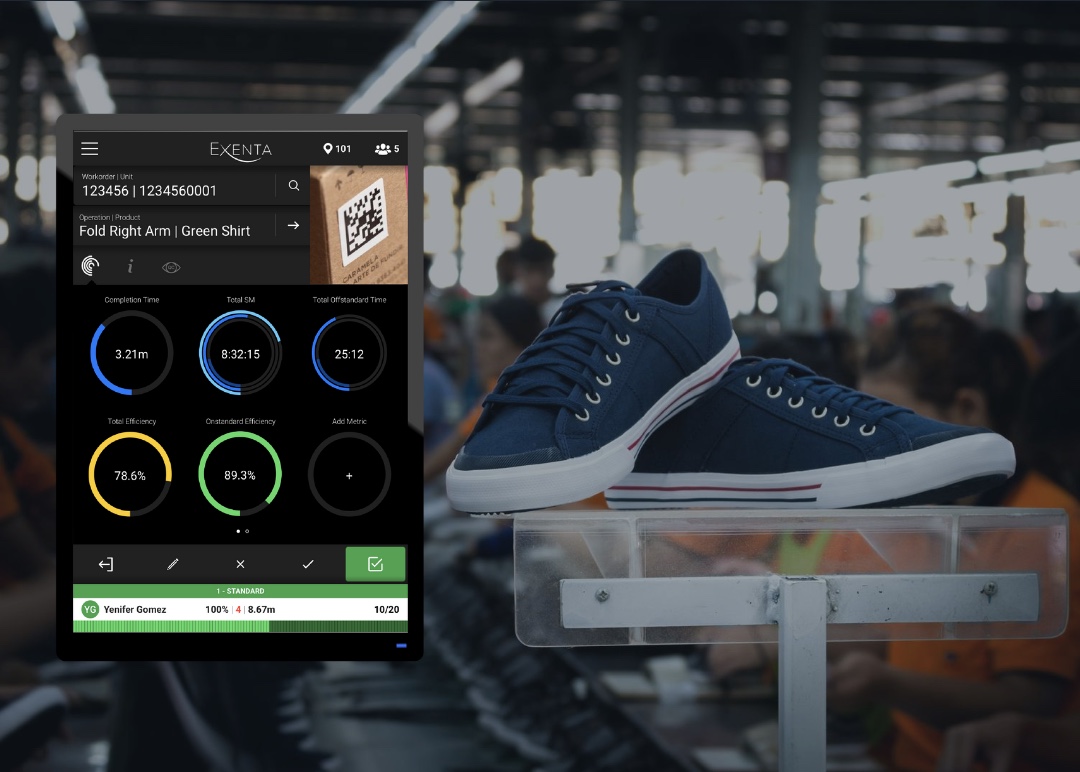

Exenta Launches Powerful New SFC Interface

-

PLM vs. ERP: What Are the Differences?

-

6 Reasons Efficient SFC Software is the Key to Success

-

Optimizing Your Fashion Supply Chain Management Process

-

How to Leverage Technology in the Era of Fast Fashion

-

5 Facts and Statistics About the Fashion Industry

-

Global Apparel Manufacturer Uses Exenta to Innovate